sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Contact

Us:

Contact

Us:

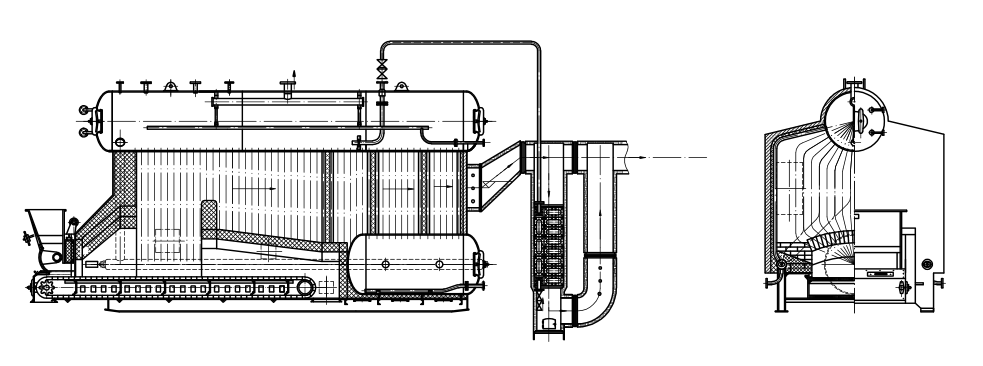

The SZL series of boilers are horizontal,double-drum, chain-grate, water-tube steam / hot water boilers.

Types: steam boiler and hot water boiler

Shipping types: packaged and assembled

Steam capacity for steam boilers: 4-35 T/H (4-6 T/H boilers are packaged and the other are assembled)

Heat capacity for hot water boilers: 2.8-29 MW (2.8-4.2MW boilers are packaged and the other are assembled)

Working pressure: 0.7-2.5 MPa

Steam temperature: 184-400℃

Hot water temperature: 95-300℃

Combustion type: chain grate furnace

Fuel: bituminous coal, dry-burning coal, hard coal, ligneous coal, firewood (sawdust), grass residue, rice chaff, etc.

Manufacturing and Design Technique Features:

1.The key processing technology of steel and tube cutting, plate rolling and drum drilling, etc adopts advanced CNC machining process, which can decrease the assembly stress and prolong the working life.

2.Steel tube cutting, end polishing, rust cleaning and bending are processed by advanced CNC.

3.The whole production line is automatic.

4.We adopts advanced automatic unionmelt welding process to ensure the welding quality. All the vertical and circular welding seams will be inspected by 100% X-ray detection.

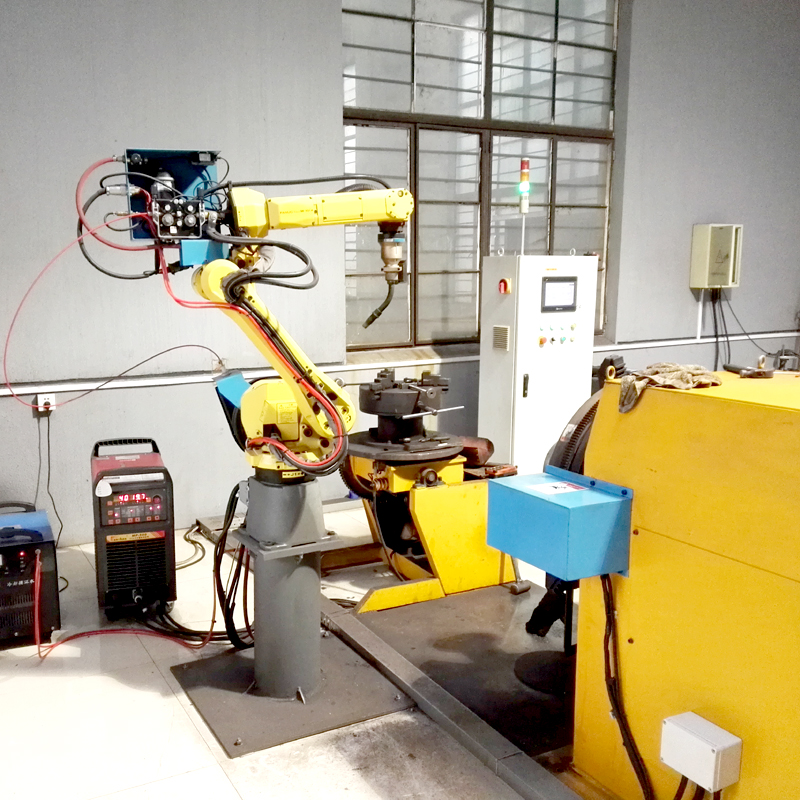

5.Tubes and flanges are welded together by robot.

6.Chain grates are all made by ZOZEN and before delivery the chain grates must be tested in cold state for 48 hours.

7.Chain grate combustion furnace with reasonable arch structure and air distribution can fit different fuel.

Control and Safety System

1.The control and safety systems are interlocked in an electric control cabinet.

2. Alarm system

- Sound-light alarm of high and super-high steam pressure;

- Sound-light alarm of high and lowe water limit level;

- Sound-light alarm of pressure loss in the water pumps;

- More safety devices are designed and connected with the electric control cabinet (ECC).

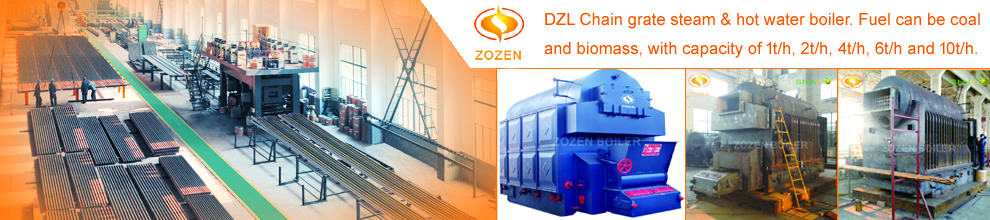

Boiler Production

|

|

|

|

|

|

|  |

|

Other Equipments

1. Economizer

|

|

|

2. Cyclone

|  |

|

3. Scrubber

|

|

|

4. ID fan and FD fan

|  |

|

5. Slag remover

|

|  |

6. Steam distributer

|

|

|

7. Electric control cabinet

|

|

|

Oversea Market

Workshop

|  |  |

|  |  |

|  |  |

|  |  |

Model List

| SZL4-1.25-AⅡ | SZL4-1.60-AII | SZL4-2.45-AⅡ |

| SZL6-1.25-AⅡ | SZL6-1.60-AⅡ | SZL6-2.45-AⅡ |

| SZL8-1.25-AⅡ | SZL8-1.60-AⅡ | SZL8-2.45-AⅡ |

| SZL10-1.25-AⅡ | SZL10-1.60-AⅡ | SZL10-2.45-AⅡ |

| SZL15-1.25-AⅡ | SZL15-1.60-AⅡ | SZL15-2.45-AⅡ |

| SZL20-1.25-AⅡ | SZL20-1.60-AⅡ | SZL20-2.45-AⅡ |

| SZL25-1.25-AⅡ | SZL25-1.60-AⅡ | SZL25-2.45-AⅡ |

| SZL30-1.25-AⅡ | SZL30-1.60-AⅡ | SZL30-2.45-AⅡ |

| SZL35-1.25-AⅡ | SZL35-1.60-AⅡ | SZL35-2.45-AⅡ |

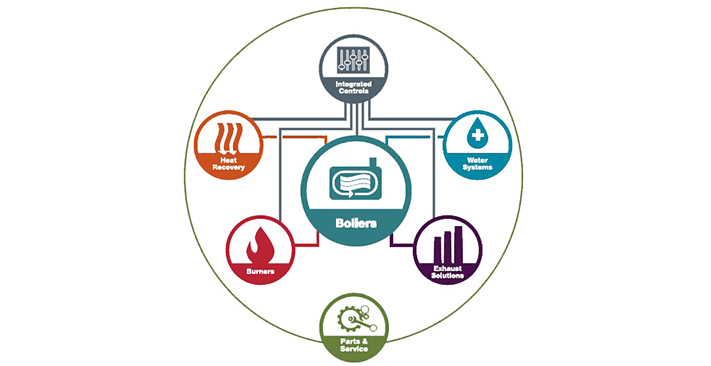

Total Integration goes far beyond boilers.

Efficiency and quality don't end with our boilers. ZOZEN complete integration produces the most efficient boiler solutions in the world. Completely designed, engineered, manufactured, integrated, and serviced by our team, our systems don't have a single outsourced component to jeopardize compatibility or performance. If you are looking for the best-quality boiler systems with the lowest emissions and highest efficiencies, you are looking for Zozen.

I want to comment