sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

As a backbone of Pakistan’s economy, the textile industry represents one of the country’s most vital manufacturing sectors, driving exports and employment. To support its rapid industrial growth and sustainability goals, many textile enterprises are turning to cleaner, more efficient energy solutions. Among the key contributors to this transformation is ZOZEN Boiler, which has supplied advanced biomass-fired boiler systems to numerous textile plants across Pakistan. Through tailored engineering, reliable performance, and localized service, ZOZEN’s biomass boilers have become trusted partners in powering the nation’s textile production with green energy.

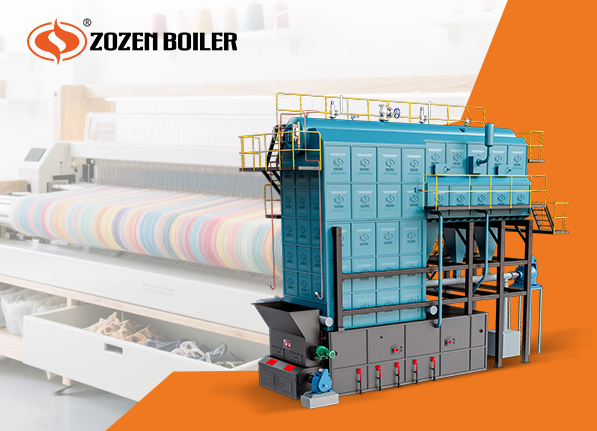

ZOZEN DZL biomass-fired horizontal type steam boiler

With years of presence in the Pakistan market, ZOZEN Boiler has continuously aligned its technology with the industry’s evolving energy structure. At major industry events such as Textile Asia Karachi 2024 and the 2025 Pakistan Textile Exhibition, ZOZEN showcased its series of 10–40 ton three-drum biomass boilers, which captured wide attention for their high thermal efficiency and strong fuel adaptability.

Designed to operate with various locally available fuels such as biomass pellets, rice husks, palm shells, and wood chips, these boilers deliver up to 10% higher thermal efficiency compared with conventional models and help textile producers reduce fuel costs by 30–40% compared with gas-fired systems. This flexibility not only addresses the high cost of coal in Pakistan but also supports enterprises in reducing carbon emissions and meeting environmental standards—an increasingly urgent demand in global textile supply chains.

Behind this success lies ZOZEN’s strategic insight: adapting its products to local fuel characteristics and industrial habits. Instead of applying a one-size-fits-all approach, ZOZEN engineers have developed combustion systems and furnace designs that match Pakistan’s biomass resource conditions, ensuring reliable operation and high efficiency across diverse textile applications.

Stable and continuous steam generation is critical for textile processes like dyeing, drying, and finishing. ZOZEN’s reciprocating grate technology plays a central role in ensuring that reliability. By using a dynamic grate mechanism that continuously stirs and turns the fuel bed, the system promotes complete combustion, minimizes clinker formation, and significantly reduces unburned carbon in ash.

20-ton DZW series reciprocating grate biomass boiler

Real-world projects demonstrate these technical strengths. At Kohinoor Mills, a 20-ton DZW series reciprocating grate biomass boiler successfully utilized both palm shells and recycled construction wood as fuel, cutting operating costs while maintaining strong performance for the company’s large-scale fabric production. Similarly, at Lucky Textile Mills, a 25-ton biomass boiler achieved over 88% thermal efficiency through a water-cooled wall structure and advanced radiant heating design. Its intelligent control system automated feeding, combustion, and ash removal, further enhancing operational stability and reducing labor intensity.

Beyond technical excellence, ZOZEN Boiler has built a comprehensive localized service system to support customers throughout Pakistan. Through a professional agency network, ZOZEN provides one-stop consultation, on-site installation guidance, and technical training. Engineering teams stationed in the region ensure quick response for commissioning and maintenance, enabling textile enterprises to maintain steady production without interruption.

Looking ahead, ZOZEN Boiler will continue to deepen its cooperation with Pakistan’s industrial sector, offering efficient, eco-friendly, and intelligent biomass energy solutions. With a commitment to innovation and local engagement, ZOZEN stands ready to empower Pakistan’s textile enterprises on their journey toward cleaner and more competitive production.

I want to comment