sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

On the edge of the tropical jungles of Sumatra, Indonesia, the palm oil industry operates around the clock, turning fresh fruit bunches into one of the world’s most important agricultural commodities. For palm oil producers, a stable and reliable thermal energy supply is not a supporting function—it is the backbone of continuous production. Recently, Wuxi ZOZEN Boiler Co., Ltd. successfully delivered and commissioned a 15 t/h SZL series coal-fired steam boiler for a well-known local palm oil enterprise in Indonesia.

Indonesia has abundant coal resources, but the local fuel structure is complex. Bituminous coal and lean coal coexist, and fuel properties often vary between batches. High moisture content and unstable calorific values are common, especially during the rainy season. The customer’s original boiler system struggled to cope with these conditions. Incomplete combustion, unstable thermal efficiency, and frequent steam shortages during peak crushing periods became recurring issues.

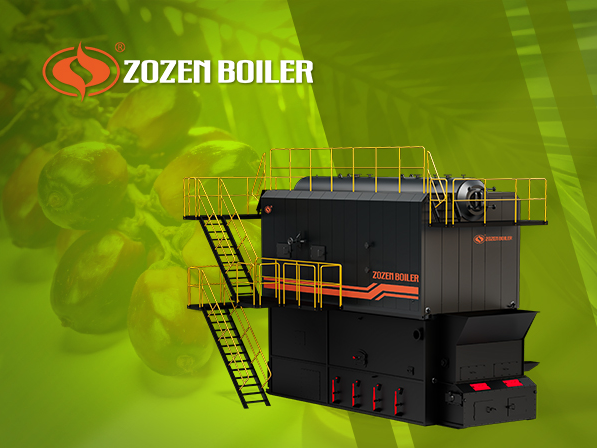

ZOZEN SZL Coal-Fired Steam Boiler for Indonesia Palm Oil

Based on a detailed understanding of local fuel characteristics and process requirements, ZOZEN Boiler recommended the SZL series chain grate coal-fired steam boiler. This series is a horizontal double-drum water-tube boiler designed for medium-capacity industrial steam demand and long-term continuous operation.

One of the key advantages of the SZL series lies in its combustion system. The boiler adopts a chain grate combined with an independent air chamber design. This structure allows precise zonal air distribution across the grate surface, ensuring that different sections of the fuel bed receive appropriate combustion air. Whether firing high-volatile bituminous coal or harder-to-burn lean coal, the system can maintain stable and complete combustion. This strong fuel adaptability is particularly important for Indonesian palm oil plants, where coal quality can vary significantly.

Inside the furnace, the SZL series boiler uses a dense arrangement of membrane water wall tubes. This design significantly increases the radiant heat transfer area, allowing more effective absorption of furnace heat. As a result, thermal efficiency remains stable at over 81% under design conditions, helping the customer reduce fuel consumption while maintaining reliable steam output.

In terms of operation, the SZL series boiler is equipped with an advanced automatic control system. Fuel feeding, ash removal, and slag discharge are all automated, minimizing manual intervention. This not only improves operational safety, but also reduces labor intensity and simplifies daily management, allowing the customer to maintain stable 24-hour operation during peak processing seasons.

Beyond equipment performance, ZOZEN Boiler’s export-oriented service system played a key role in the success of this project. With extensive experience in overseas markets, particularly in Southeast Asia, ZOZEN provided full-process support, including fuel analysis, system design, installation guidance, commissioning assistance, and operator training.

After commissioning, the boiler quickly achieved stable operation. According to feedback from the palm oil enterprise, the new system effectively solved long-standing fuel adaptability issues, while the automated operation significantly improved production management efficiency. Continuous operation during the crushing season is now achieved without added operational pressure.

If your palm oil plant or industrial facility is facing challenges related to fuel variability, steam stability, or operating costs, contact ZOZEN Boiler to discuss a tailored coal-fired steam boiler solution designed for your local conditions and production needs.

I want to comment