sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Drying preservation is a common method of fruit and vegetable treatment, which can not only preserve fruits and vegetables for a long time, but also keep the nutritional value and unique flavor. The dried food is quite popular with the consumers. As a solid supplier of drying boiler equipment, Wuxi ZOZEN Boiler Co., Ltd. has produced a full range of boiler products with reliable quality. ZOZEN Boiler has reached cooperation with several well-known food enterprises, such as Mengniu, Chia Tai Group, Cho Heng Rice Vermicelli Factory Co., Ltd. and so on.

Serbia is rich in various fruits and vegetables due to its unique climatic conditions. Lipkom Doo company follows the trend and vigorously develops characteristic agriculture. Now it has developed into an agricultural enterprise specializing in the production, packaging and sale of fresh, frozen fruits, vegetables and dried fruits. In the processing process of fruits and vegetables, the company has adopted a professional low-temperature drying process, in order to ensure that the nutritional value will be preserved to a greater extent, to make sure the good taste of the finished product. As an important drying equipment in its production line, whether the boiler can generate heat energy stably will directly affect the product quality.

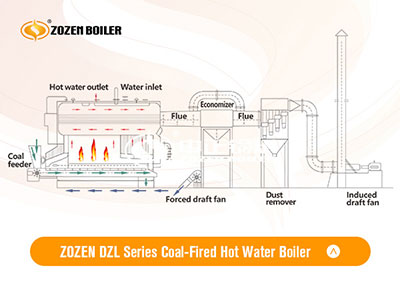

After receiving the requirements of Lipkom doo Company, the sales manager of ZOZEN Boiler made a detailed understanding of the processing technology of fruits and vegetables and recommended a set of DZL series chain grate hot water boiler according to the actual working conditions. This series of boilers is reasonably arranged with furnace arch, furnace wall, furnace heating surface, with high-efficiency heat-transfer threaded smoke pipes, so that the heat transfer efficiency is high. The combustion equipment adopts light chain grate, and it will be tested for 72 hours before leaving the factory to ensure that the tightness is moderate and won’t go wrong.

Schematic diagram of ZOZEN coal-fired hot water boiler

Furthermore, the boiler provided by ZOZEN Boiler adopts automatic control system, which is easier for the operation and maintenance. The fuel supply, ash discharging and slag discharging operations of ZOZEN chain grate boiler are mechanized. Coal feeding and slag discharging are convenient, the grate has stepless speed change, and few operators and maintenance personnel are needed. Also, the boiler is equipped with advanced interlock protections, which lays a solid foundation for the rapid development of the company.

Since the commissioning in 2015, the boiler has served and supplied the heat energy for the production line, especially during the harvest season of fruits and vegetables. During July to September, Lipkom doo is busy with the harvest of fruits and vegetables in Serbia and makes dried food. ZOZEN chain grate boiler operates at full load or even overload to ensure that all fruits and vegetables are processed in time.

I want to comment