sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Contact

Us:

Contact

Us:

The 10 mw SZL biomass boiler offers over 86% efficiency in turkey, and flexible biomass fuel options for industrial and institutional heating projects.

Introduction

Product thermal capacity: 4.2-17.5 MW

Working pressure: 1-1.25 MPa

Outlet temperature: 95/70℃, 115/70℃

Available fuel: Biomass molding granules, wood chip, corn cob, saw dust, palm shells, rice husk

Available industries: Heating, hotels, schools, hospitals

SZL series biomass boilers have high thermal efficiency and strong overload capacity, and are suitable for various fuels, such as biomass or coal. This boiler adopts a unique structural design to ensure that the fuel is completely burned. Graded air supply and special furnace arch structure decrease the NOx emissions to 100mg/m³. Different biomass raw materials are analyzed by numerical simulations, thermal efficiency is more than 86%.

Technical advantages

Broad Fuel Compatibility

Compatible with biomass pellets, rice husks, wood chips, corn cobs, sawdust etc.

Efficient Fuel Combustion

ZOZEN chain grate and independent air bin ensure thorough fuel combustion

Thermal Efficiency>86%

Densely arranged water-cooled walls in the furnace offer large radiation area

Simple Operation

Advanced controls automate fuel supply, ash removal, and slag discharge

Product Parameters

| Model | Rated thermal power(MW) | Rated working pressure(MPa) | Rated output water temperature(℃) | Return water temperature(℃) | Maximum transport size(m) (L×W×H) |

| SZL2.8-0.7/95/70-M | 2.8 | 0.7 | 95 | 70 | customized size |

| SZL4.2-1.0/115/70-M | 4.2 | 1 | 115 | 70 | 7.0×2.7×3.5 |

| SZL5.6-1.0/115/70-M | 5.6 | 1.0 | 115 | 70 | 6.9×3.2×5.3 |

| SZL5.6-1.25/130/70-M | 5.6 | 1.25 | 130 | 70 | 6.9×3.2×5.3 |

| SZL7.0-1.0/115/70-M | 7 | 1.0 | 115 | 70 | 7.9×3.3×3.5 |

| SZL7.0-1.25/130/70-M | 7 | 1.25 | 130 | 70 | 7.9×3.3×3.5 |

| SZL14-1.0/115/70-M | 14 | 1.0 | 115 | 70 | 11×3.2×3.5 |

| SZL14-1.25/130/70-M | 14 | 1.25 | 130 | 70 | 11×3.2×3.5 |

| SZL21-1.0/115/70-M | 21 | 1.0 | 115 | 70 | 9.9×3.3×3.6 |

| SZL21-1.25/130/70-M | 21 | 1.25 | 130 | 70 | 9.9×3.3×3.6 |

| SZL29-1.0/115/70-M | 29 | 1.0 | 115 | 70 | customized size |

| SZL29-1.25/130/70-M | 29 | 1.25 | 130 | 70 | customized size |

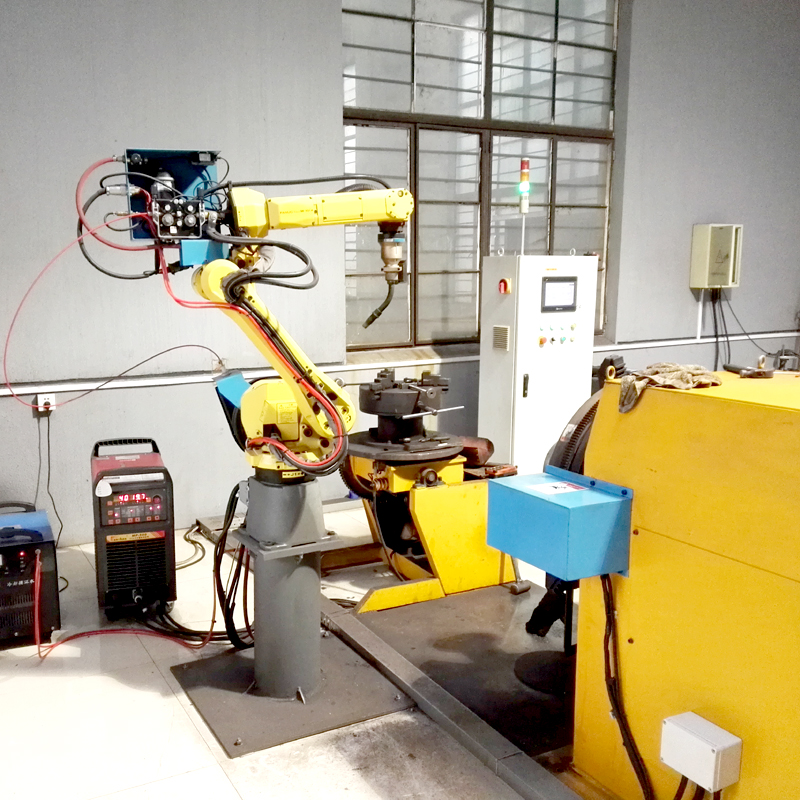

Workshop

|  |  |

|  |  |

|  |  |

|  |  |

Oversea market

What is the service life of an SZL biomass boiler?

The service life of an SZL biomass boiler typically exceeds 20 years when designed, operated, and maintained according to standard industrial practices. Proper fuel preparation, routine ash removal, and regular inspection of heat-transfer surfaces significantly extend equipment lifespan.

Does the SZL biomass boiler require frequent fuel size control?

Yes. To ensure stable combustion and high efficiency, biomass fuel size and moisture content should be reasonably controlled. Uniform fuel size helps maintain even fuel feeding on the chain grate and reduces combustion fluctuations.

How does the SZL biomass boiler adapt to seasonal load changes?

The SZL boiler features strong load regulation capability and can operate stably under partial or peak loads. By adjusting fuel feeding rate and air distribution, the boiler maintains efficient combustion during both heating peak seasons and low-demand periods.

I want to comment