sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Contact

Us:

Contact

Us:

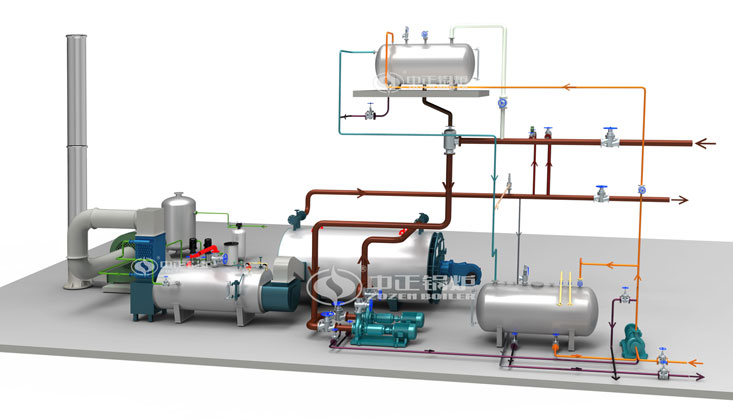

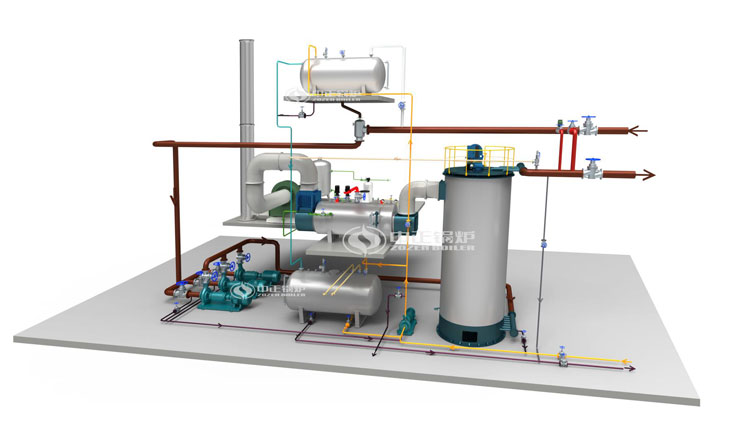

YY(Q)W(L) series of horizontal gas-fired thermal oil (hot oil,thermal fluid) heaters are used in many industrial applications where efficiency and accurate temperature control between 100℃ and 320℃ are required. They work in the way of heating directly thermal fluid in the pipes with the high temperature smoke. With the help of forced circulation oil pumps, the fluid with high temperature goes into the heat-required equipments, like dryer, and then comes back to the heater and is re-heated again. ZOZEN has many years experience in this field and we offer can a broad range of products, service and support.

Heat capacity : 0.7-14MW (60X104-1200X104Kcal/h)

Rated working pressure : 0.8MPa (8 bar)

Rated working temperature : 320℃

Manufacturing Process Features

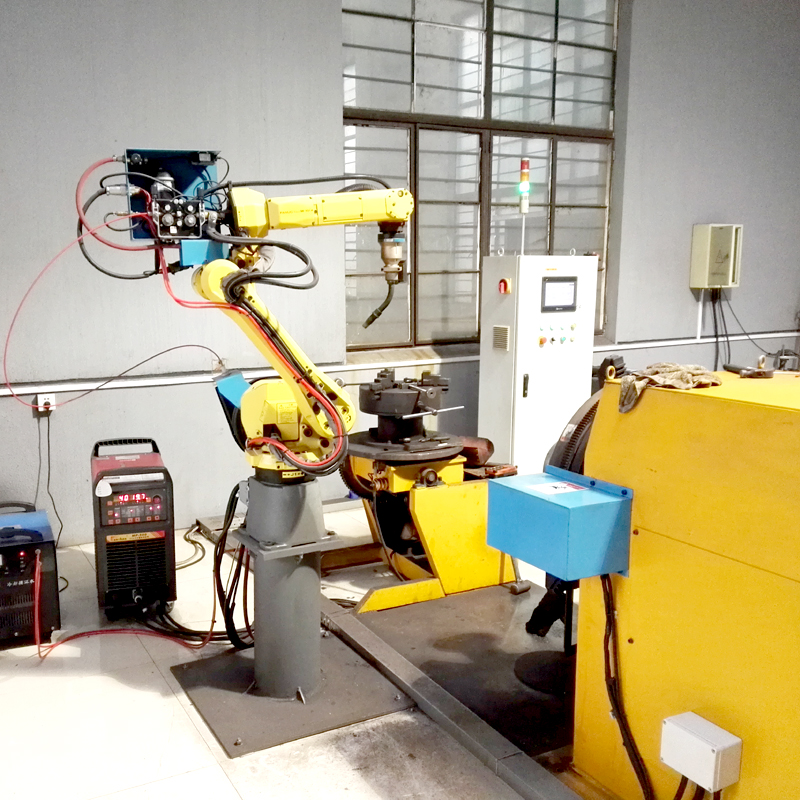

1. The laying-off of steel tube adopts CNS 3D laser cutting.

2. The manufacture of round coil pipes adopt CNC COIL PIPE PRODUCTION LINE and shape at one time.

3. Steel tube butt welding adopts automatic argon arc welding technology and welding should be done by X-ray real time imaging.

4. 100% hydraulic test.

5. Use superior insulation material inside and stainless steel plate outside. Reduce heat loss most and improve the operating environment.

6. Cone coil pipe effectly protect the furnace wall and burner

Boiler Features

1. High thermal efficiency, unique structure, the thermal efficiency can reach more than 90%.

2. The proprietary combustion technology and the structure of heating coiler can absolutely avoid the overheat and damage of coilers in common conditions.

3. The top of inner coiler is designed into cone-shape, which can prevent the casting material on the top fall off in high temperature.

4. High safety. When abnormal conditions happen, safety interlock system starts up to protect the heater.

5. Accurate temperature control. The oil temperature in the outlet can be controlled within ±1ºC.

6. The integrated compact structure only cover a small working area.

7. Easy to install, operate and maintain.

8. The boiler can be equipped with a waste heat boiler in the rear, if users need hot water or steam from the heating system. That makes full use of the exhausted smoke to achieve energy-saving and environmental protection.

Control and Safety System

• Functions achievement

- Steady and high temperature is offered and meets the requirements of load;

- Automatic load regulation is achieved;

- Safety interlock and feedback protection are achieved in the abnormal conditions;

- Early warning, alarm, fault display and locking are achieved;

- Continuous and steady working is achieved;

- Manual and automatic working can be achieved as customer’s requirement.

• Main controls

- Control the oil pressure at key spots

- Control the oil temperature at key spots

- Control the smoke temperature at key spots

• List of system main monitoring points

- Inlet oil temperature

- Outlet oil temperature

- Oil flow rate

- Inlet oil pressure

- Outlet oil pressure

- Oil level in the expansion tank

- Oil level in the storage tank

• List of display, alarm and interlock

| Detection point | Location | Display | Control | Alarm | Interlock |

| Oil inlet temperature | ECC / at site | √ | |||

| Oil outlet temperature | ECC / at site | √ | √ | √ | √ |

| Low fluid flow rate | ECC / at site | √ | √ | √ | |

| Low air pressure of burner | ECC / at site | √ | √ | √ | |

| Gas pressure | ECC / at site | √ | √ | √ | |

| Gas consumption | ECC / at site | √ | |||

| Smoke temperature | ECC / at site | √ | √ | ||

| Cold air temperature | ECC / at site | √ | |||

| Flame fault | ECC / at site | √ | √ | √ | |

| Conditions of oil pump | ECC / at site | √ | √ | √ | |

| Outlet pressure of oil pump | ECC / at site | √ | |||

| Inlet pressure of oil pump | At site | √ | |||

| Fluid level of expansion tank | ECC / at site | √ | √ | ||

| Temp. of expansion tank | ECC / at site | √ | √ | ||

| Inlet/outlet pressure of fluid | ECC / at site | √ | √ | √ | √ |

| Inlet/outlet pressure of heater | At site | √ |

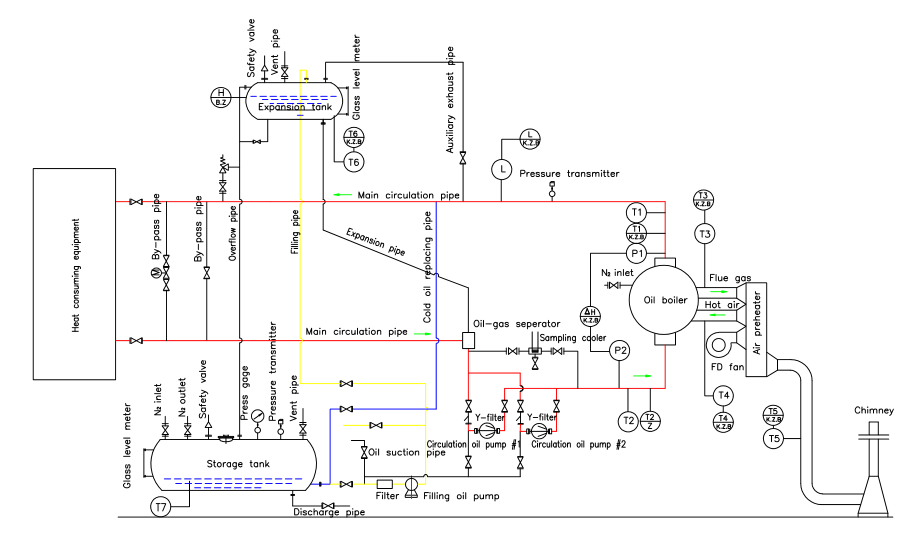

Working Principle

Oversea Market

Workshop

|  |  |

|  |  |

|  |  |

|  |  |

Model List

| YY(Q)W-700Y(Q) | YY(Q)W-1000Y(Q) | YY(Q)W-1200Y(Q) |

| YY(Q)W-1400Y(Q) | YY(Q)W-1800Y(Q) | YY(Q)W-2400Y(Q) |

| YY(Q)W-2800Y(Q) | YY(Q)W-3500Y(Q) | YY(Q)W-4200Y(Q) |

| YY(Q)W-4600Y(Q) | YY(Q)W-6000Y(Q) | YY(Q)W-7000Y(Q) |

| YY(Q)W-8200Y(Q) | YY(Q)W-9400Y(Q) | YY(Q)W-10500Y(Q) |

| YY(Q)W-12000Y(Q) | YY(Q)W-14000Y(Q) |

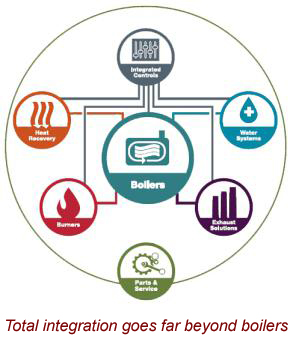

Efficiency and quality don't end with our boilers. ZOZEN complete integration produces the most efficient boiler solutions in the world. Completely designed, engineered, manufactured, integrated, and serviced by our team, our systems don't have a single outsourced component to jeopardize compatibility or performance. If you are looking for the best-quality boiler systems with the lowest emissions and highest efficiencies, you are looking for Zozen.

I want to comment