sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

ZOZEN Boiler has developed the third generation of biomass-fired boiler which has been successfully applied by Danmao Textile. The good operating condition of this set of boiler gives us a strong confidence to further officially launch the new product - DZL series tri-drum biomass-fired boiler.

ZOZEN launched the DZL series tri-drum biomass-fired boiler

Jointly developed by ZOZEN Boiler and Shanghai Jiaotong University, the second generation of ZOZEN biomass-fired boiler has taken the lead in solving the problems of conventional biomass-fired boilers via scientifically arranging the furnace arch, furnace wall, furnace heating surface and secondary air. This time, ZOZEN officially launched the third generation of biomass-fired boiler product - DZL series tri-drum biomass-fired boiler.

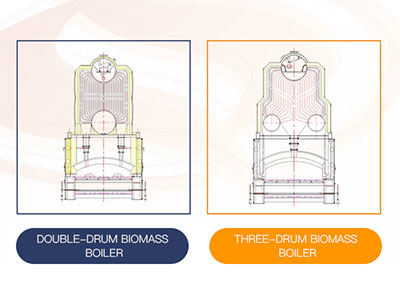

On the basis of SZL series double-drum longitudinal biomass-fired boiler, DZL series tri-drum biomass-fired boiler optimizes the problem of frequent boiler shutdown for dust removal. The boiler with the double-drum structure has the dead angle of ash accumulation, so the dust of biomass fuels is difficult to be discharged from the small ash hopper on both sides of the convention tube bundles due to the small density and strong adsorbability of the dust. Therefore, ZOZEN optimizes and designs the tri-drum boiler. The ash hopper is set in the middle of the lower part of the flue gas duct, so there is no dead angle of ash accumulation, which can make the boiler normally operate for a longer timer and greatly reduce the frequency of boiler shutdown for dust removal.

The structure upgrading of ZOZEN third generation of biomass-fired boiler

Meanwhile, the dust produced by burning biomass fuel is easily discharged into the ash hopper, which reduces the burden of dust collector and is more eco-friendly under the same conditions. It is also worth mentioning that the dead angle of the flue gas scouring the heating surface is small, so it is not easy to form a vortex, thus the heating surface has higher heat transfer efficiency, which further improves the thermal efficiency of the boiler. The tri-drum biomass-fired boiler has reached a higher level in the aspects of technology, performance and indexes on environment protection.

In the textile, printing and dyeing industry, whether shaping, dyeing and other processes or driving the drying equipment all depend on the support of boiler. As a leading enterprise manufacturing the worsted fashion fabrics in China, Danmao Textile had higher requirements on the boiler stability and continuity. Recommended by ZOZEN technicians, Danmao Textile purchased a set of DZL series tri-drum biomass-fired boiler.

So far, the boiler has been running stably for more than three months in a good condition. According to the boiler operation records, compared with the double-drum boiler, the third-drum boiler is more suitable for burning biomass for less ash accumulation, good combustion and sufficient output. The boiler can keep the operation for a long time, which can reduce the work burden of boiler operator and improve the production efficiency.

The DZL series tri-drum biomass-fired boiler is stably operating at Danmao Textile

With the gradual promotion and application of the DZL series tri-drum biomass-fired boiler, ZOZEN has reached the cooperation with Wujiang Xinyi Textile, AEN PALM OIL PROCESSING in Sri Lanka and has good market response.

I want to comment