sales@zozen.com

sales@zozen.com

- WhatsApp: 0086-18861589035

-

Contact

Us:

Contact

Us:

1. Product thermal capacity: 7-116 MW

2. Working pressure: 10bar-16bar

3. Available fuel: Natural gas, coke oven gas, blast furnace gas, carbon black tail gas, biogas, diesel, heavy oil, light oil, crude oil, etc.

4. Available industries: Heat supplying, hospital, colleges and universities.

| Model | Thermal Efficiency | Working Pressure Range | Water Temperature Range |

|---|---|---|---|

| SZS7-1.0/115/70-Y(Q) | ≥98% | 1.0 MPa | ≤115°C (supply), 70°C (return) |

| SZS10.5-1.0/115/70-Y(Q) | ≥98% | 1.0 MPa | ≤115°C (supply), 70°C (return) |

| SZS14-1.0/115/70-Y(Q) | ≥98% | 1.0 MPa | ≤115°C (supply), 70°C (return) |

| SZS14-1.25/115/70-Y(Q) | ≥98% | 1.25 MPa | ≤115°C (supply), 70°C (return) |

| SZS21-1.25/130/70-Y(Q) | ≥98% | 1.25 MPa | ≤130°C (supply), 70°C (return) |

| SZS29-1.25/130/70-Y(Q) | ≥98% | 1.25 MPa | ≤130°C (supply), 70°C (return) |

| SZS46-1.6/130/70-Y(Q) | ≥98% | 1.6 MPa | ≤130°C (supply), 70°C (return) |

| SZS58-1.6/130/70-Y(Q) | ≥98% | 1.6 MPa | ≤130°C (supply), 70°C (return) |

| SZS70-1.6/130/70-Y(Q) | ≥98% | 1.6 MPa | ≤130°C (supply), 70°C (return) |

| SZS116-1.6/115/70-Y(Q) | ≥98% | 1.6 MPa | ≤115°C (supply), 70°C (return) |

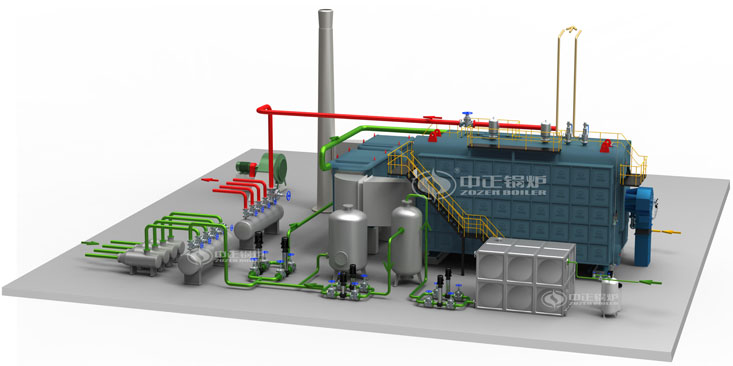

SZS boiler body is the structure of longitudinal double drums and D-type chamber combustion. The furnace is on right side and the convection tube bundle are on left side. The flexible supports of boiler are in the middle and two ends of the lower drum, and it can secure the whole boiler body to expand sideways. There are narrow-space membrane cooling tube walls on the four sides of furnace. The left membrane wall makes the furnace and the convection tube bundle separated. The rear of convection tube bundle is a kind of tube-decreasing and staggered structure, and the front is an aligned structure. The flue gas generated from furnace combustion flows from the rear outlet of furnace into the end of combustion chamber, convection tube bundle area, and then turns from the front-left of furnace to the spiral finned tube economizer, and next flows into smoke duct and chimney and finally exhausts into atmosphere.

|  |  |

Industry: Paper Capacity: 15MW Pressure: 12.5 bar | Industry: Chemical Capacity: 29MW Pressure: 12.5 bar | Industry: Heating Capacity: 10.5MW Pressure: 10 bar |

1. Program function modularization and efficient interlocking alarm function;

2. Automatic start and load PID automatic regulation function;

3. Soft manual control function;

4. Automatic control function to water level (only for steam boiler);

5. Timing and antifreezing control function (only for hot water boiler);

6. Automatic control function to circulation water pumps (only for hot water boiler);

7. Burner fault interlock protection;

8. Fuel gas pressure abnormity fault interlock protection;

9. Fuel gas leakage interlock protection;

10. Water level and water shortage dual interlock protection;

11. Ultrahigh steam pressure dual interlock protection (only for steam boiler);

12. Ultrahigh exhaust gas temperature interlock protection;

13. Power-off fault interlock protection;

14. Extra-high water level fault alarm (only for steam boiler);

15. Water pump fault alarm;

16. Circulation water pump running interlock (only for hot water boiler);

16. Extra-high outlet water temperature interlock protection (only for hot water boiler);

17. Extra-high outlet water pressure interlock protection (only for hot water boiler);

18. Motor overload interlock protection (only for hot water boiler);

19. Ultrahigh furnace temperature fault interlock protection (only for SZS boiler);

20. Ultrahigh furnace pressure fault interlock protection (only for SZS boiler);

|  |  |

|  |  |

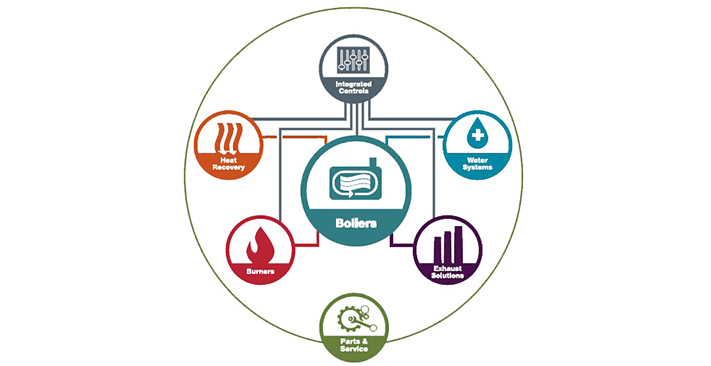

Total Integration goes far beyond boilers

Efficiency and quality don't end with our boilers. ZOZEN complete integration produces the most efficient boiler solutions in the world. Completely designed, engineered, manufactured, integrated, and serviced by our team, our systems don't have a single outsourced component to jeopardize compatibility or performance. If you are looking for the best-quality boiler systems with the lowest emissions and highest efficiencies, you are looking for Zozen.

I want to comment